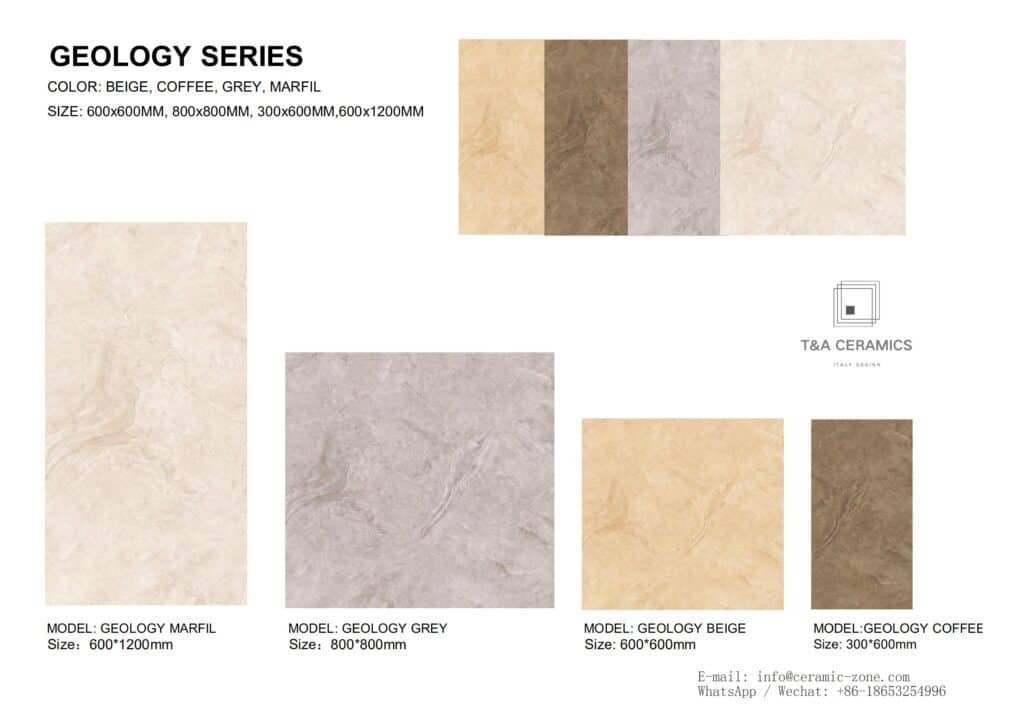

Tiles of various colors and patterns have become the main decoration materials in modern homes, and the use of them will directly affect the appearance of each home’s interior decoration. With the improvement of manufacturing technology, the use of ceramic tiles has become more and more. Coming more and more.

Table of Contents

History of ceramic tiles

Ceramic tile is a building decoration material made of clay, quartz sand and other raw materials. The surface of the tile will appear stone or porcelain, which has the characteristics of high hardness, acid and alkali resistance, and environmental protection. It is mainly used in building exterior walls or interior decoration use.

We all know that China is the hometown of ceramics. After the ancients continued to mature in pottery technology, pottery was no longer limited to a variety of dailies necessities, and began to use to pottery in construction, such as using pottery in building drainage channels and layings the ground.

The earliest documented use of ceramic tiles is Egypt. People made various shapes by hand from clay, put them in a fire and dried them, then took the blue glaze from the molten copper to dye it and made the earliest ceramic tiles with patterns.

Around the same time, ceramic tiles appeared in the Middle East. This type of ceramic tiles came in various colors and styles. For example, the classic striped tiles seemed to achieve better decorative effects.

During the European Renaissance, ceramic tiles also developed in an unprecedented way and the range of applications became more and more extensive. People have given each tile an artistic flavor, which is all handmade. Today, many old buildings in Europe can still be seen Such tiles. The production of modern ceramic tiles has been fully mechanized, and the styles, and patterns of ceramic tiles have become more and more. Ceramic tiles are almost the main material for building decoration.

Classification and production process

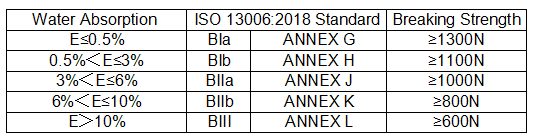

Tiles are usually divided into three categories based on water absorption

- The first type has a water absorption rate below 3%. Porcelain tiles, also known as quartz tiles, are generally laid on the ground.

- The second type of water absorption is about 10% or less. Stone bricks can be spread on the ground or wall.

- The third type of water absorption is about 50% or less. Pottery bricks are very suitable for spreading on the wall. Generally, they are not spreading on the ground.

The production process of ceramic tiles can be said to be the “refining” of fire and soil. If the whole process is subdivided. It will take hundreds of processes to form.

The raw materials for ceramic tiles include plastic raw materials such as black mud or white mud, which are the basis of ceramic tiles; ridged raw materials such as quartz, which determine various properties of the ceramic tile; solvent raw materials such as feldspar, which determine the toughness of the ceramic tile. From the soil, the ingredients need to be tested before mining, and then various raw materials are proportioned.

Various ingredients are not very uniform. They will enter the ball mill through a conveyor belt. The ball mill is equipped with wear-resistant balls. Water and various additives must be added to the ball mill. After several hours of ball milling, the raw materials will become 0.1~ The 0.3 mm fine powder will eventually become mud.

The mud must remove also ferrous inside. A strong magnet with a magnetic force of 9000 gauss is used to remove all iron impurities. The sludge passes through a screening system to separate the impurities from the raw materials with large diameter particles. The sludge enters the drying tower for drying and dewatering.

The sludge is sprayed by pressure into a mist, which is then dried and dewatered with hot air. The sludge is then left to dry. It becomes particles with good flowability.

The dried powder is fed by a conveyor belt into the hopper of the press and pressed by a brick press to form an embryo body that meets the density requirements. A computer can control every process.

The later process will be based on different types of tiles, and the production process and equipment are different, such as glazed (porcelain glazed tiles), unglazed (polished tiles), screen printing, rubber roller printing, 3D inkjet printing, full polishing Wait.

Taking porcelain glazed tiles as an example, the pressed embryo body can be glazed by spraying or glazing. The glaze spraying is to spray the glaze slurry onto the embryo body in a mist form through high pressure.

Glaze dripping is to let the glaze slurry flow down from a high place, forming a waterfall and pour it on the embryo.

There are different patterns on the tiles, which are completed by the printing process. At present, the main technology used on the market is 3D inkjet technology, and the designed patterns are printed directly onto the surface of the tile using a high performance inkjet printer. This technology makes the pattern realistic and three-dimensional, and it is also the best printing technology for ceramic tiles.

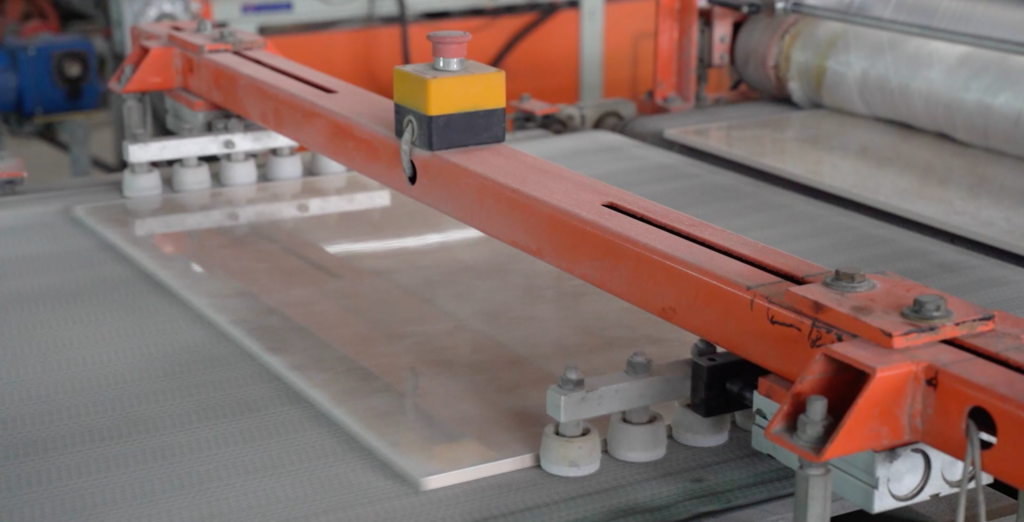

The printed tiles have to go through the most important process, which is firing. After firing, the strength of the tiles will be very high. The tiles are sent through the roller table into the kiln. The entire firing process must be preheated. Firing and cooling are completed in the kiln.

The ceramic tiles shrink during the firing process at more than 1,000 degrees Celsius, and at this point they become real ceramic tiles. The ceramic tiles must be polished and the polishing line must be trimmed, flattened, polished, chamfered and other processes must be performed. The surface of the ceramic tile can be ground and polished using grinding heads with different meshes. To achieve the purpose of antifouling, a layer of antifouling agent is also applied to the surface of the tiles.

Finally, the ceramic tiles must undergo quality control and packaging before they are sent to the store for sale.

How to routinely test tiles

Matters that require attention Usually, when buying ceramic tiles, sales personnel use scissors to scrape the tiles (surface hardness), spray water on the tiles (non-slip surface) and sprinkle soy sauce on the tiles (resistance to soiling) to test the performance of the tiles. Is this test method credible?

The Mohs hardness method is used to test the surface hardness of ceramic tiles. There are ten grades in total, and the hardness of scissors is generally below grade 4. It is interesting to note that the national standard GB/T 4100-2015 does not specify the hardness of ceramic tiles.

The professional anti-slip test consists in applying a special lubricant to the tiles, slowly tilting the tiles and the person slips at this angle of inclination. The angle of inclination at this point is the anti-slip degree of the tiles. The test standard GB/T 26542-2011 and the new standard GB/T 37798-2019 will also be introduced soon.

The professional test method for the degree of soiling of the tiles is to dribble three representative pollutants, chromium chloride, iodine and olive oil, onto the surface of the tiles and place them for 24 hours to obtain the anti-slip degree by various methods. The demonstration of the tiles is therefore small. There is still a certain gap between the tests and the scientific research.

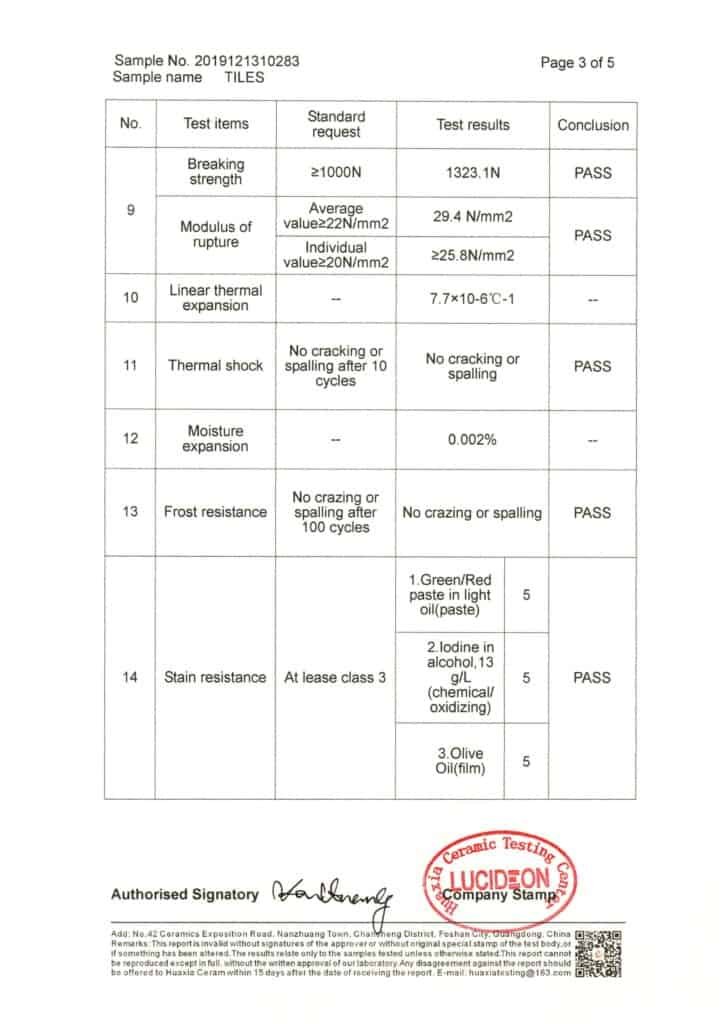

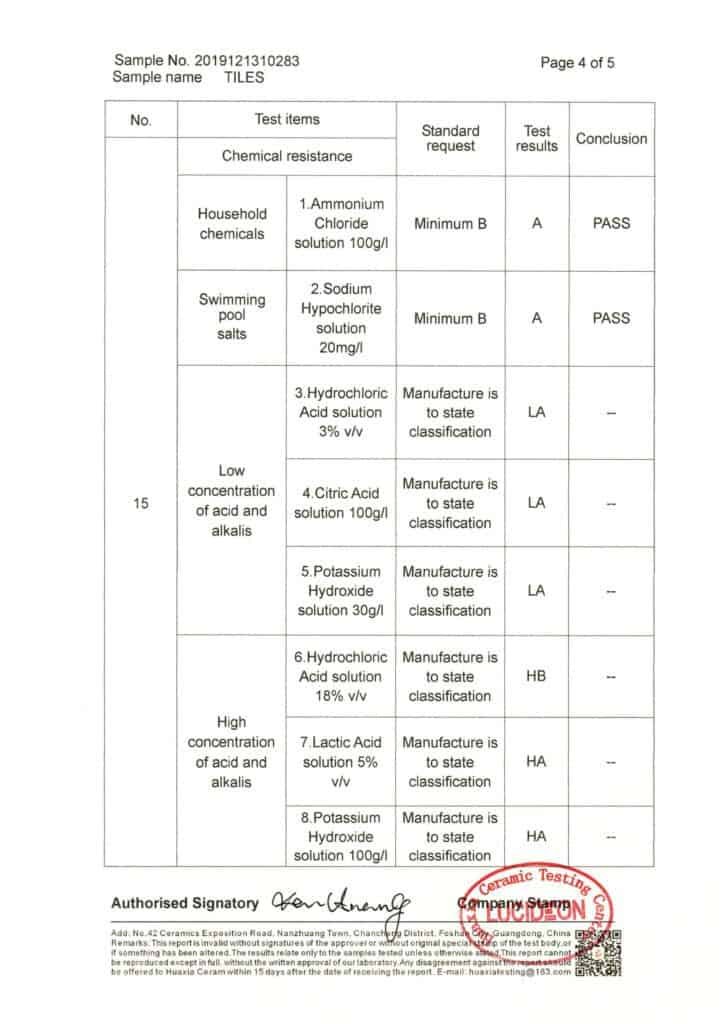

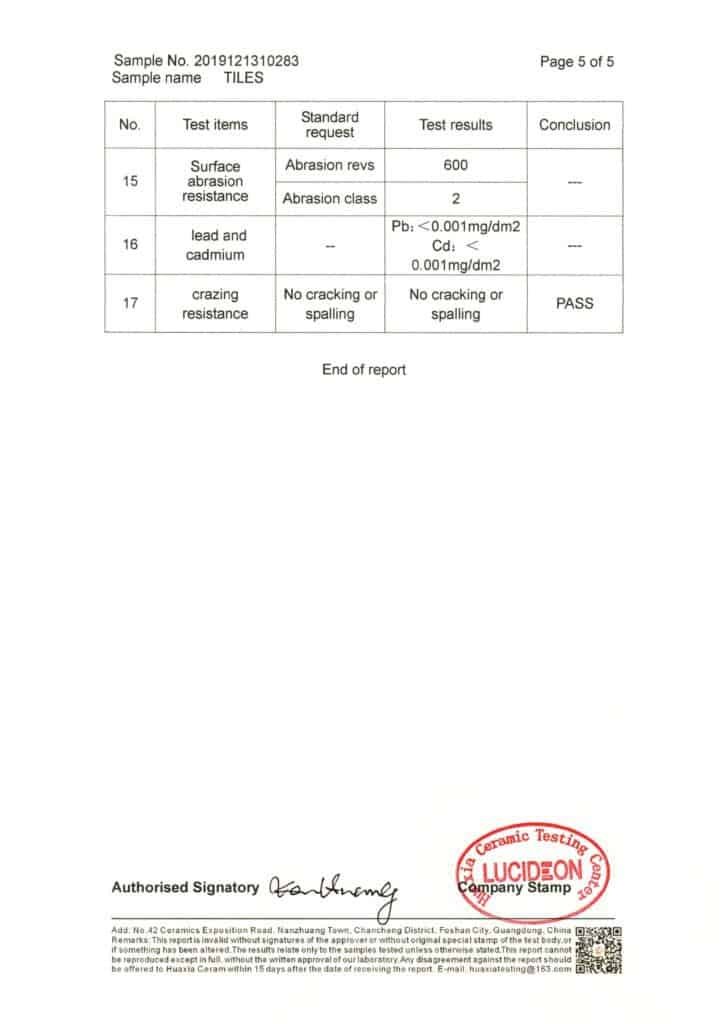

The testing of ceramic tiles also includes: dimensional defects, coefficient of friction, wet expansion, glaze crack resistance, frost resistance, chemical resistance, lead and cadmium leaching, color difference, water absorption, apparent porosity, apparent relative density and bulk density, modulus of rupture and breaking strength, impact resistance, abrasion resistance, linear thermal expansion, thermal shock, etc. Dozens of tests, these test items have national standards. The test standard can refer to GB/T 3810.

To meet the decoration needs of people for thousands of years, ceramic tiles have been constantly changing, from polished tiles to glazed tiles, mosaic tiles and antique tiles. Now some people predict that the surface of the tile will be a liquid crystal surface in the future. What type of tile do you want? It seems that ceramic tiles will also bring about a revolution in this era of great changes in various industries.