T&A CERAMICS is a tile manufacturer and was established in 2001. We have 6 production lines which include 2 wall tile lines and 4-floor tile lines. Also, we pay attention to our decor tiles. With more than 20 years of tile business experience, T&A CERAMICS will give you a detailed introduction to floor tiles and wall tiles and DECOR.

Table of Contents

What is floor tile?

Floor tiles are a kind of tiles which is used for decoration materials for the floor. The floor tiles are fired with clay. And it has various specifications. Floor tiles are strong, pressure and wear-resistance, and moisture-proof. At the beginning of floor tiles development, most of the floor tiles were unglazed tiles. For example, soluble salt, double loading, and so on. Later, with the continuous development of technology, the floor tiles currently produced by T&A CERAMICS are glazed. The glazed floor tiles have a more decorative effect than unglazed tiles. They are mostly used on the ground and floors of public buildings and civil buildings.

There are many varieties of floor tiles. According to the material difference, we have porcelain tiles and ceramic tiles. And according to the surface technology, they can be divided into glazed tiles and unglazed tiles. According to the surface finish, floor tiles can be divided into polished and matte tiles. Also according to the different users can divide interior floor tiles and also outdoor floor tiles.

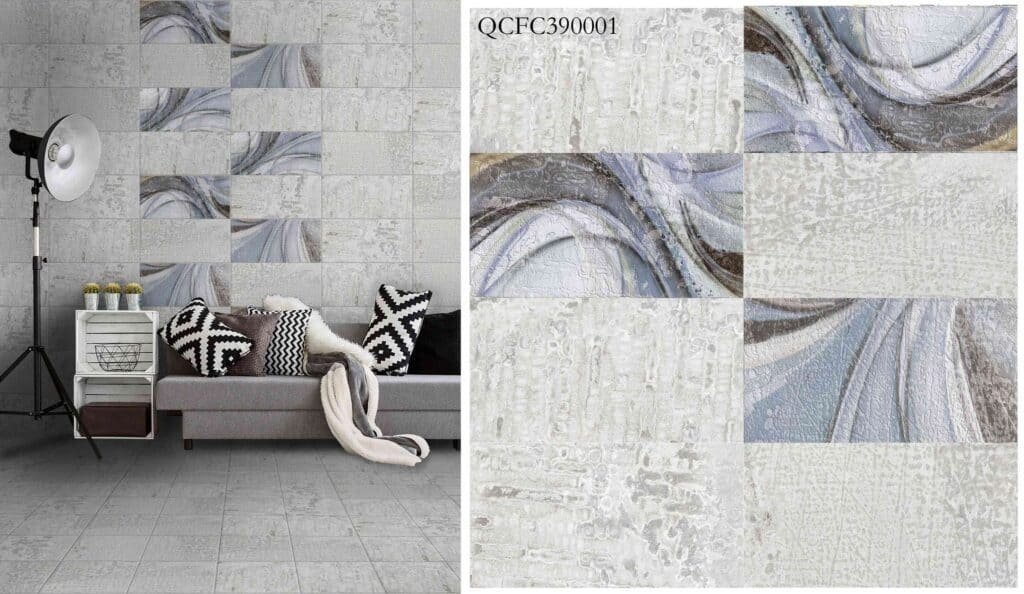

What is wall tile?

Wall tile is a kind of tile suitable for the wall of the rooms, kitchens, balconies, and some other places. The tiles have stable physical properties, anti-slip, stain-resistant, and hard. There is no need to be concerned about cleaning and generally, you can use water or special use of medical alcohol to clean the wall tiles.

Generally speaking, wall tiles can be divided into 2 categories: interior wall tiles and exterior wall tiles:

Interior wall tiles

For wall tiles, it pays more attention to aesthetics, more stain-resistant, lighter, and thinner. At the same time, the back is also relatively rough, which is conducive to the paste of the wall, wear-resistance, and hardness. For the sizes we do for wall tiles are 30x45cm, 30x60cm, 25x75cm, 30x80cm, 40x80cm, 30x90cm.

So far, most of the time, the interior wall tiles T&A CERAMICS supplies are used for the bathroom and kitchen most. Since interior wall tiles usually have higher water absorption, and after absorbing the water and it may have some little color difference. However, after the tiles dry and the color will become normal.

Exterior wall tiles

Exterior wall tiles are mainly used for the decoration and protection of building exterior walls. Exterior wall tiles not only decorate the whole building but also play an important role in protecting the wall. Because of their acid and alkali resistance and stable physical and chemical properties, and also prevent cold and heat preservation.

What is the difference between floor tiles and wall tiles?

1. Usage

Generally speaking, wall tiles decorate for walls to avoid damage, water splash, or pollution. Floor tiles are the materials that are mainly used to decorate the ground and floor.

2. Process characteristics

Wall tiles are mostly glazed tiles, which are composed of three parts: the green body, the bottom glaze layer, and the top glaze layer. Floor tiles are fired from clay and have a variety of specifications.

3. Physical characteristics

Wall tiles are ceramic products, and floor tiles are usually porcelain products. This is a big difference between wall tiles and floor tiles. This difference can be reflected in the selection of clay ingredients to the firing process. The water absorption of wall tiles is more than 10%, which is several times higher than that of floor tiles with water absorption of about 1%.

What is the production process of floor or wall tile?

1. Raw materials: Various raw materials are stored in a sealed storage warehouse after entering the factory

2. Batching system: According to the process requirements, use a forklift to load into the hopper of the feeder, the dust generated during the loading process is absorbed by the cloth dust collector, and the absorbed powder is used as raw material

3. Ball milling: The raw material workshop is equipped with a mill according to the formula provided by the technical department. After do grinding to a certain fineness according to the specified time. Then do the testing, sizing, and sieving

4. Drying tower: There is a coal slurry furnace to provide the heat source, and the drying tower is sprayed to dry powder.

5. Press forming: The powder is pressed by a press to make a green body.

6. Bisque-fired: The green body made by the press is fired into a green body in a kiln.

7. Glazing: The biscuit made of biscuit is applied with the base glaze and top glaze and then enters into the printing

8. Printing: The printing glaze is printed on the glaze surface through a printing machine

9. Glaze firing: the printed blank is fired into a glazed tile by a kiln

10. Edging: The burned glazed tiles are rectified

11. Drying: After water milling, the tiles are dried in a drying kiln to enter the selection.

12. Inspection and packaging: The dried tiles are graded, separated by the inspection workshop. Then and the finished products are packed.

FLOOR TILES

Compare with wall tiles, the floor tiles production process has some differences. So we will choose full polished tiles to share its production process.

1.Raw material processing: the above raw materials are ground and dried into powder for molding.

2.Forming: use high tonnage automatic tile press to form.

3.Drying: Dry the formed tiles to increase their strength for the next surface decoration process.

4.Glazing and printing: Glazing and printing are important processes in the production of antique tiles. The main process control points in the production are concentrated on the glazing line. Many tile products use printing technology to improve the surface pattern and improve their taste. In the past few years ago, glazed tiles mainly used in screening printing produce the effect of non-repetitive patterns. Later, we use roller printing to achieve antique and natural patterns. At present, inkjet printing technology is gradually adopted in production. According to new technologies used in production, the tiles can show more designs. The printed tiles are finally covered with a special transparent glaze for polishing

5.Firing: Firing is the heart of ceramic production. We need to make the tiles with low water absorption. So the firing temperature has been increased to more than 1,000°C. Also, to achieve special decorative effects for tiles, besides using primary firing, times need secondary firing and tertiary firing techniques in the production of tiles.

6.Glaze polishing: We use a full polished technical process to do the tiles. According to the glaze polished, the surface of the tiles is bright and soft, smooth and not protruding. It appears crystal clear and translucent. The stone grain under the glaze is clear and natural. Crystal glaze film coverage makes the overall level more three-dimensional.

7.Inspection: The current production is still manual quality inspection. The main items are size, deformation, chromatic aberration, cracks, delamination, missing corners, and surface defects, etc.

What we can do for decor?

Besides the floor tiles and wall tiles, we also can do DECOR tiles. In T&A CERAMICS Decor list has Encaustic tiles and also Mosaic tiles.

About mosaic tiles, we have our own cutting production lines, so customers can choose our inkjet designs and let us know your required size and shape, then we can do the mosaic tiles according to your requirement.

Encaustic tile also named encaustic cement tile, originated from the 18th century European pure handmade brick method, its characteristics of colorful, thick and moist, durable, and long-lasting tile.

For the encaustic cement tile, we have more than 200+ awesome designs for different markets. We can provide size with 10X10 CM, 15X15CM, 178X220CM, 200X230CM, 200X200CM, 300X300CM, and 300X600CM; type with Fireplace Encaustic Tile, glossy encaustic tile, Handmade Encaustic Tile, Hexagonal Encaustic Tile, Mexican Encaustic Tile, Moroccan Encaustic Tile, and Victorian Encaustic Tile.

Generally speaking, cement tiles, four spell one to be able to see the effect, because four cement tiles can show a complete pattern. And different styles of patterns can be adapted to different decoration styles, decoration shades, making the house more charming and different!